|

| |

|

Developed in collaboration

with Australian multi-award winning Producer/Engineer David

Nicholas (US & UK #1s with Pulp, INXS, Elton John, Bryan Adams)

the Prodigal Dual Channel Strip & Monitor Station is a

world class analog strip for use in pro studio, location, or

home recording and mastering. This blog follows a single unit

through a typical production build. |

|

1. Empty Chassis.

Straight out of bubble-wrap and ready to begin. |

|

|

|

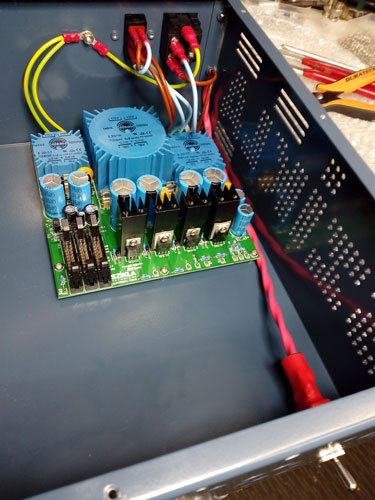

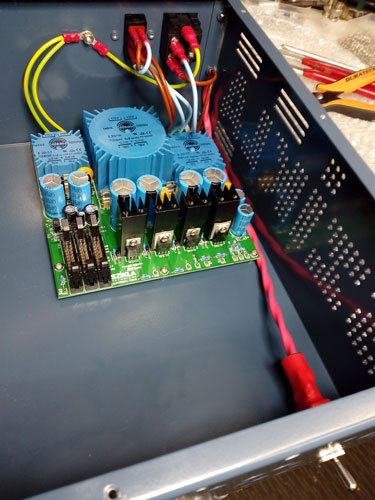

2. Power Supply Installed.

Includes IEC inlet, Voltage Selector, and front panel Power

Switch. |

|

|

The Prodigal uses 3 Torroidal Power Transformers

instead of the cheaper option of a single one with lots of

output windings that magnetically couple. This means that the VU and

relay circuits are completely isolated from the analog audio

circuitry - for super silent running. A third transformer feeds only the P48 supply.

Rail

voltages produced are:

T1: +48 phantom

T2: +15, +9, -9, -15 audio

T3: +5 digital metering, +12 relay switching.

Note the Star Ground Post on the rear panel,

which is the only point where Safety, Analog, Digital,

and Chassis Grounds meet. From any point in the

Prodigal's circuitry, there is only one path back to

here, which eliminates internal ground-loops and current noise

from neighbouring circuit nodes. This simple idea can be

challenging to implement, but is a big factor in creating the

Prodigal's scarily quiet noise floor. The Monitor Section alone

boasts a signal to noise ratio of 104dB!

Keen observers will also notice there is no electric fan

to annoy you during mixing. Fans in audio gear, well, blow. The

Prodigal is designed to run cool, and only needs the four small

black heatsinks for the audio rails, to which an additional

cooling fin will be added later in the build process.

|

|

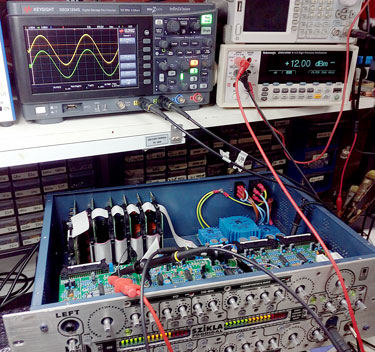

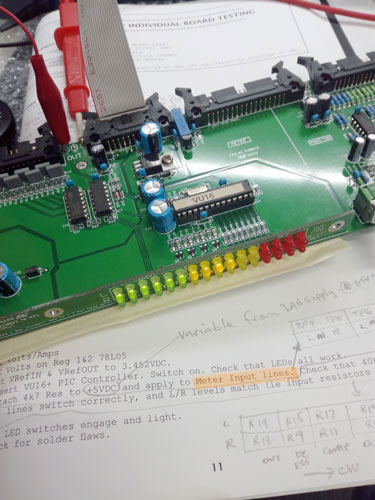

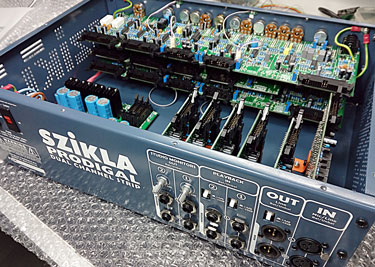

3. Pre-Assembly Test and

Alignment.

All Boards |

|

|

Prior to assembly, all boards are tested against

a massive checklist to ensure there are no mistakes in the

build, and that they operate within their designated electrical

parameters.

Voltages, current consumption, signal levels, gain and switching

are checked and adjusted where applicable.

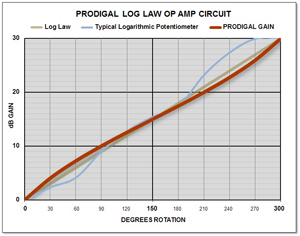

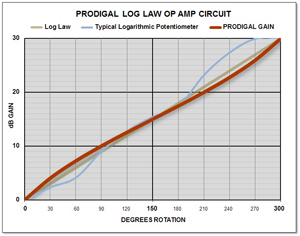

One of the finer settings performed is alignment of the

electronics behind the 0 to 30dB Input Gain knob, which is

tweaked to a tolerance of one hundredth of a dB. Also, to overcome

the tremendous imprecision of logarithmic pot tapers, this gain

section boasts an innovative design wherein a linear potentiometer

enslaves a cascading pair of op-amps in a highly mathematical way. Across

30dB of adjustment, the gain curve tracks to within 1dB

of a perfect log law.

Special matched components are also installed at this time, such

as the gain-reduction FETs (one for the De-Esser and one for the

Compressor) which need to operate in perfect concert between Left and

Right channels. Pre-calibrated parts are soldered in

sequence, then each board pair is numbered and kept together

during the

rest of construction. |

|

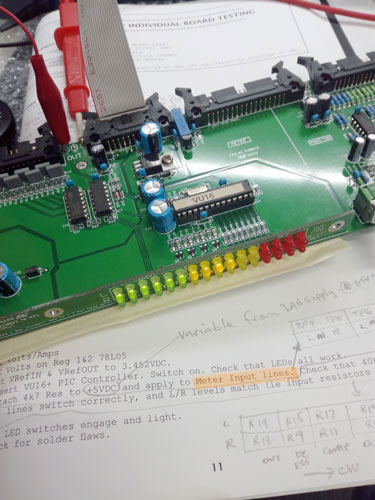

4. Pre-Assembly Test and

Alignment. Microphone Preamplifier

(egghead

warning!)

warning!) |

Input Amplification Test |

Special treatment is given to the commissioning of

the Microphone Preamp board.

The Prodigal has no input transformer to deliver

a free level-boost prior to

amplification. The Mic signal is taken directly into the preamp, so

every part of the front end has to be sweet and clean.

Transistors are hand-matched and thermally paired

for super low-noise operation. Input resistors are also matched,

and impedances are kept on the low side of the IEC permitted

range. That's because we think audio signals sound better when

driving a lower impedance. Raise an eyebrow if you like, but we've done

double-blind tests and folks can hear the difference; now it's

part of the Prodigal sound. Unlike transformers, resistors also

present a uniform input impedance across all frequencies. We

like that too.

With Mic inputs, switching is important. You need to be able

to change level and impedance between mic and line, apply a 20dB

pad, invert phase, and apply 48v phantom. With the main inputs

at rear, mic signals would have to travel a long way exposed to

other circuitry before arriving at the front-panel switches, and

in cheapo devices that's how it works. In the Prodigal we take

the switches to the back panel instead

–

via high

quality relays. The switches switch the relays, and the relays

switch the audio. That keeps the signal path short, and delivers

the cleanest possible soundwave prior to amplification.

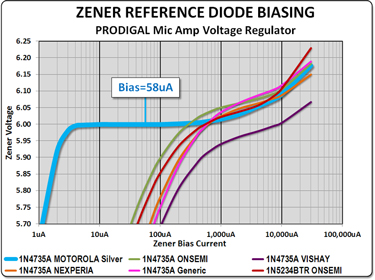

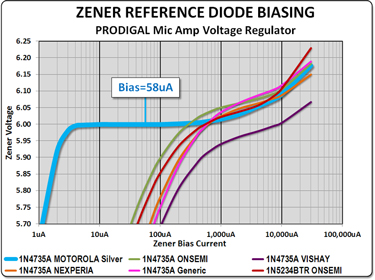

Mic levels are very small, and fluctuations on the

power lines can cause large harmonic distortions if they bleed

through. On each mic amp power supply, the Prodigal uses a zener-referenced

regulator circuit which subdues about 10,000 times more voltage

flutter than an on-chip regulator. Zener diodes are

classified as being of a fixed voltage, but the volts actually

vary with the current passing through them

–

as the graph on the

left shows. We use 1N4735A vintage Motorola diodes (the blue

line) which are not made any more. You can see as current

increases there is a flat spot where the voltage

doesn't change. We run the Motorolas right in that spot,

at 58 microamps bias. That means Thor (the mighty god of ending

your career) can zap your power supply with a 50% voltage spike,

causing a 50% change in diode current, and the result

will be (at 38 or 87uA) NO change of zener voltage and the microphone amp won't

even notice.

We continue to blow our lunch money testing

modern diodes (even with the SAME PART NUMBER) and so far

they're all useless

– no flat spot, so

no gig. Five

are on the graph, but we've tried heaps.

Pre-assembly testing looks at all the above, plus

a bunch of less interesting housekeeping. I like the photo of the

Motorola diode. He's a sexy boy.

|

Transistors Matched and Paired |

High Dependability

Axicom Relays |

Vintage Motorola Silver Reference Diode |

|

Razor-Flat Blue Line of the Vintage

Motorola Diode

|

|

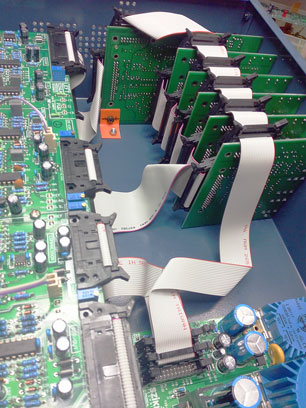

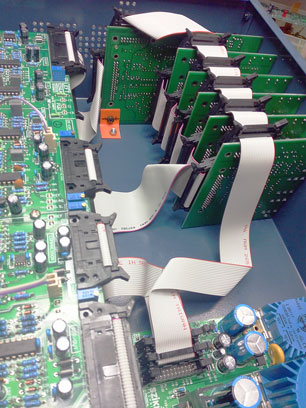

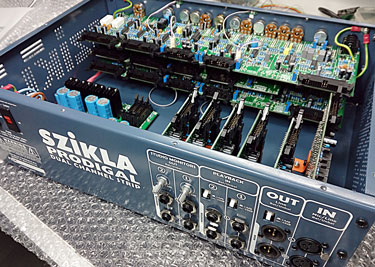

5. Assembly

All Audio Boards |

Front Panel Contol Boards |

Installation of the Prodigal circuit boards is fairly straightforward,

but they still want to be handled like new-born puppies. There

are three control boards for the front panel, six in/outs for

the rear, and the power supply makes an even ten. Once they're

all fitted, six IDC ribbon cables similar to those used in

computers provide the complete network of inter-board power and

signal busses. Prior to insertion, connection pins are cleaned,

and connectors are sprayed with electro-lube.

Much has been done to suppress or eliminate

electromagnetic interference within the unit. Each board has a

guard-ring etched around its perimeter to shunt radiated energy

away from audio and back to ground. Along the ribbon cables, no

two signals travel side by side; instead, they are always

separated by a grounded strand that guards against one

signal-pair injecting crosstalk into another. There are actually

more strands used as guards than for any other purpose.

Furthermore, power and signal are never allowed on the same

ribbon.

As hinted above, audio travels along the buss in

balanced pairs, which is an unusually fussy arrangement for

board-to-board signals. This is so any received radiation not

whisked away by the guard-strands can be cancelled by a balanced

receiver at the end of each line.

All the careful design work which focussed on the

extraction of unwanted signals has paid off in silence, with

input noise way down at -118dBu, and remarkably, mains hum

levels (unmeasurably) even lower than that.

|

Front Boards In |

Rear Panel In-Out Boards |

|

All Buss Lines In |

|

All Boards In |

|

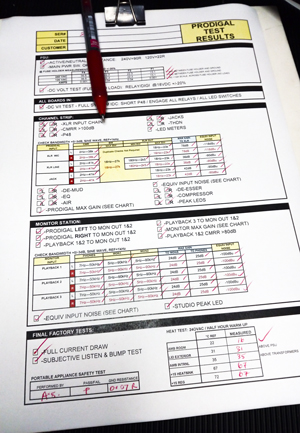

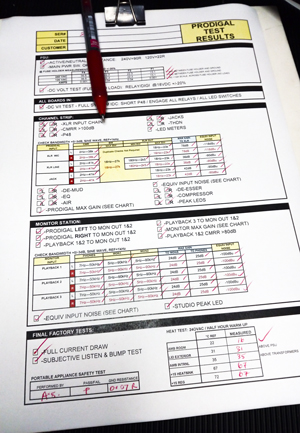

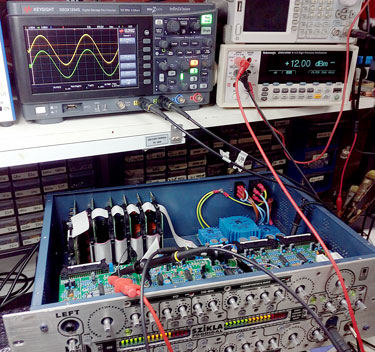

6. Testing and

Aligning

All Systems |

Temporary Dummy Front Fascia |

Nobody wants to get testy during testing, so a dummy

front fascia is attached to

ease the headache of wondering which knob is which. Afterwards,

the dummy will be replaced by a pristine real one. Knobs and

other scratchable externals also stay under wraps until the last possible moment.

First up, the power buss is broken out into its

seven separate rails, which are checked against expectation

under various load conditions, and any Prodigal inconsistencies

are corrected.

When we are satisfied that the heart is beating

correctly and the blood is pumping where it should, we move on

to inspect the athletic and artistic properties of the

Prodigal's audio circuits. There are tests for each side of the

channel strip, more tests for the monitor section, and it takes

about four and a half hours to run through the full checklist.

Every input and output is examined, and a number of internal

settings are tweaked for critical performance and optimum

channel match.

The main audio signal injected is a pure

sine-wave, which facilitates reliable analyses of amplitude,

bandwidth, headroom, equalisation and distortion. Besides inputs

and outputs, readings are also taken at the L-R mix buss, and

other internal nodes. Sexy and highly accurate test equipment is

employed, to measure levels, baffle our friends and relatives,

and make us look very clever. (Trivia sidenote: even though the

idea has been workshopped by every technician in the last fifty

years, not a single one of these machines dispenses coffee.)

Eventually the form below is transcribed into a

forest of ticks and scribbles, all the audio paths are tuned to

perfection, and we are ready for final assembly.

|

Measuring Current Draw Along All The

Supply Rails At The Same Time |

Sinewave Analysis Using Raunchy Electro-Porn Gadgets |

|

Graphing Bandwidth |

|

7. Final assembly |

Adding The Cooling Fin |

First among the last things, we add an additional cooling fin to the power

supply, to draw away as much heat as possible and direct it towards the rear vents.

Then we put the lid on, and try to make the Prodigal hotter than you

are ever likely to experience it! The unit is warmed up for thirty minutes

with all LED switches on, audio clipped beyond saturation, and

the headphone amp turned up loud but playing into a

short-circuit

failure condition. We take its temperature at specific

external and internal nodes, and are yet to witness a complaint. As we said earlier, we didn't want

a fan, because fans make noise, and the Prodigal is dead

silent.

Following that torsion ordeal, the unit receives

the final

standard appliance safety test, to double-check for insulation and earth

continuity compliance.

Hooray! Now we get to fit all the good-looking

bits, and enjoy the finished product.

Off comes the dummy fascia, and on go the

potentiometer nuts. They've been kept aside till now so that

any board requiring inspection can be easily removed. A shiny

new fascia and two gold rack ears are unwrapped and fastened with hex-head

machine screws. Now the unit is finally looking like a Prodigal.

Knobs and switch-caps all get the cotton-glove

treatment... and suddenly we are done!

But wait, there's more. Before sending our baby

out into the world, there's still an important box to tick: a live

listening test with microphones, playback, headphones and nearfield monitors. This is

our favourite test, partly

because a love of listening to (loud) audio is why we started doing this for a

living in the first place, and partly because after all that

painstaking work it feels like we're just kicking back and sipping a

coffee that took us a week to get to. mmmm. Stairway to arabica!

When the neighbours start banging on our windows,

the Prodigal gets a quick polish, goes into a plastic bag and foam protectors, and

is put snugly to sleep in a double-corrugated

cardboard carton for shipping off around the world.

We are extremely proud of our Prodigal Channel

Strip, which

while still in its relative infancy has been used to create some

outstanding recordings, and is waiting to help you with yours.

I hope you have enjoyed this blog, and I thank you

for reading it. If you would like to try a Prodigal, or have any

comments or questions we would love to hear from you.

- Andy Szikla

|

Heat Check Under Crazy Load Conditions |

Appliance Safety Test |

Going Nuts |

|

Shiny

New Fascia... |

And Rack Ears |

|

Bagged And Foamed, Ready For Boxing |

Knobs And Other Fittings |

back

to top

|